Local activist apparel production in the UK supports ethical clothing practices while boosting local economies. It creates jobs, reduces waste, and encourages fair labour conditions. By producing garments locally, businesses cut emissions, shorten supply chains, and promote transparency.

Key points:

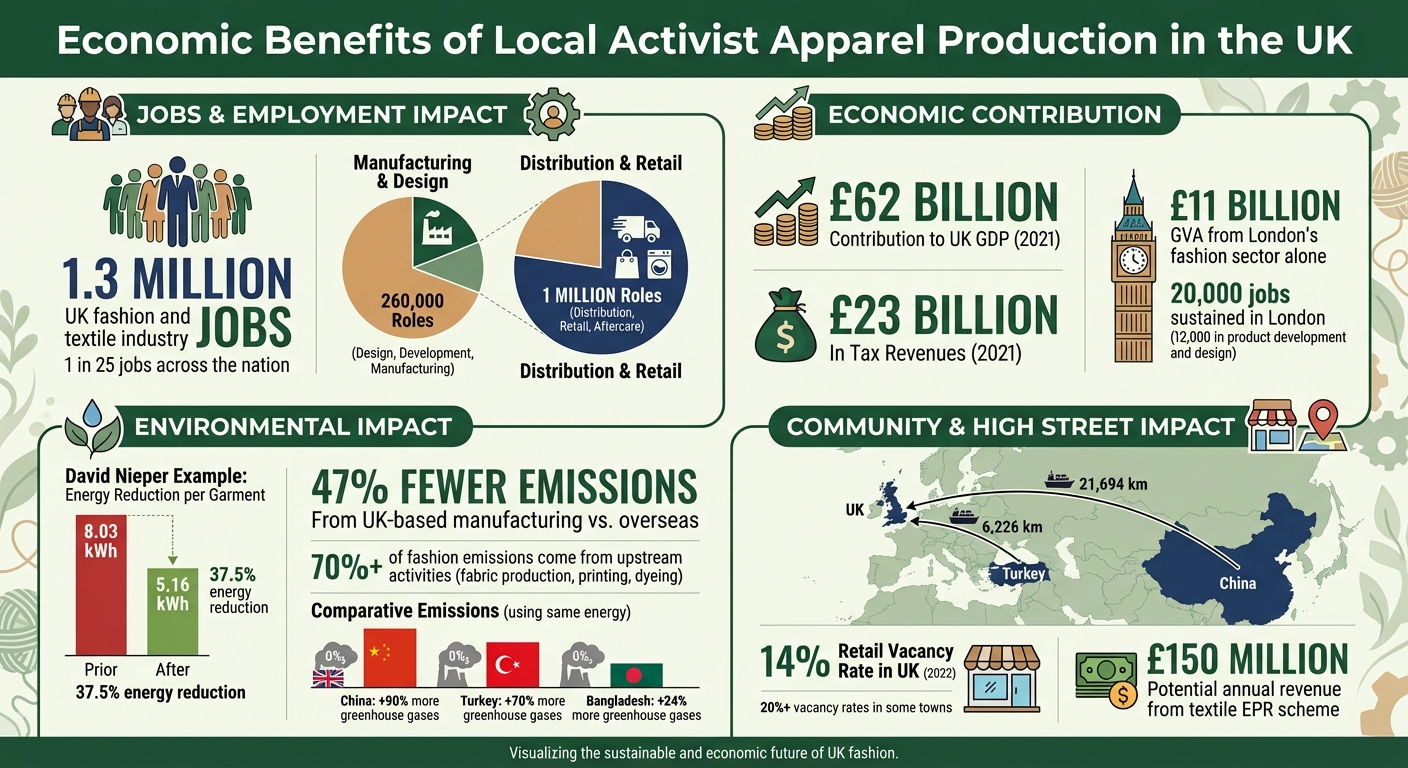

- Job creation: The UK fashion and textile industry employs 1.3 million people, with 260,000 in manufacturing roles.

- Economic impact: Every £1 spent locally benefits connected industries like printing, embroidery, and retail.

- Reduced emissions: UK-based manufacturing produces 47% fewer emissions compared to overseas operations.

- High street revival: Independent fashion brands revitalise communities by filling vacant shops and reinvesting locally.

- Challenges: High costs and limited funding hinder small producers, but policy support like grants or tax breaks could help.

Producing clothing locally strengthens communities, supports skilled workers, and aligns with ethical and environmental goals. It’s a practical way to counter the wasteful practices of fast fashion while creating long-term economic opportunities.

Economic Impact of Local UK Apparel Production: Key Statistics

Job Creation and Economic Impact

Employment Opportunities in Local Apparel Production

The UK fashion and textile industry is a significant employer, providing 1.3 million jobs - that’s 1 in every 25 jobs across the nation. Out of these, around 260,000 roles are focused on design, development, and manufacturing, while 1 million are tied to distribution, retail, and aftercare.

Local apparel production offers vital opportunities for skilled craftspeople and technical workers. Historically, Glasgow was a hub for bespoke tailoring and craftsmanship, boasting 30 bespoke tailors, 23 dressmakers, 22 shirtmakers, 21 milliners, and 5 shoemakers. Today, businesses like ReJean Denim in Glasgow are leading a revival of local production. By transforming deadstock denim and preloved jeans into fresh designs and offering repair services, they create jobs in upcycling and garment mending. This resurgence is part of a broader movement, with brands increasingly looking to source knitwear, jersey, Cut, Make and Trim (CMT), and printing services within the UK, particularly for smaller, on-demand production runs.

"This report highlights the vital contribution that the fashion and textile industry makes to the UK economy and society as a whole and its potential for future growth and positive impact." – Adam Mansell, CEO of UKFT

These employment opportunities not only support individuals but also lay the foundation for wider economic benefits through increased local spending.

The Local Multiplier Effect

When money is spent on locally produced apparel, it doesn’t just benefit the manufacturer - it ripples through the community. This local multiplier effect ensures that income generated by local businesses flows into related industries, such as printing workshops, embroidery specialists, and independent retailers. Every pound spent helps sustain these interconnected sectors.

In 2021, the fashion and textile industry contributed £62 billion to UK GDP and brought in £23 billion in tax revenues. Local production models play a key role in this by boosting direct economic activity and supporting supply chains, including logistics and specialist services. This approach not only generates wealth but also helps revive local economies, particularly in areas hit by manufacturing decline and unemployment. It’s a way to rebuild economic strength and community pride, one stitch at a time.

Revitalising High Streets and Local Economies

The Role of Independent Fashion Businesses

High streets across the UK are facing tough times, with over 14% of retail spaces sitting empty in 2022, and some towns reporting vacancy rates over 20%. Independent fashion businesses are stepping up to counter this trend, breathing life back into these areas by filling vacant units and creating inviting, dynamic retail environments.

Take ReJean Denim in Glasgow as an example. This independent brand is making waves by embracing a circular economy approach, using creative reuse strategies that keep production local. These kinds of businesses do more than just occupy empty spaces - they transform them into destinations that attract people back to the high street. By doing so, they help restore the vibrancy and diversity that town centres desperately need. This revitalisation also has a knock-on effect, boosting the local economy by encouraging the reinvestment of wealth within the community.

Community Wealth Building Through Local Ownership

Independent fashion businesses don’t just revitalise physical spaces - they also play a key role in strengthening local economies. When these businesses are locally owned, the economic benefits stay within the community. Buying from a local fashion brand means your money supports a network of interconnected services, from fabric suppliers to printers and embroiderers, all within the area.

Researcher Alis Le May highlights the impact of this local investment:

"By investing in the local makers, more jobs and better outcomes will be generated for the wider population. This is not 'trickle-down' economics as we have witnessed it, which in the words of Jason Hickel has been 'barely even a vapour'".

To put this into perspective, London’s fashion sector alone contributed £11 billion in Gross Value Added (GVA) in 2021, sustaining 20,000 jobs, including 12,000 in product development and design. When ownership stays local, these economic gains don’t just disappear - they remain within the community, creating lasting opportunities and fostering long-term growth.

Environmental and Social Benefits of Local Production

Reduced Environmental Impact Through Local Manufacturing

Producing activist apparel within the UK brings clear environmental advantages compared to outsourcing production overseas. For instance, UK-based clothing manufacturing generates 47% fewer emissions than similar operations abroad. This significant reduction is largely due to shorter transport routes and the UK's cleaner electricity grid.

The disparity in carbon emissions between countries is striking. Using the same amount of energy, manufacturers in China, Turkey, and Bangladesh produce roughly 90%, 70%, and 24% more greenhouse gases, respectively. Adding to this, the emissions from shipping are substantial, with distances from key textile hubs to UK high streets ranging from 6,226 km (Turkey) to a staggering 21,694 km (China).

Local manufacturing also offers brands greater transparency and control over their supply chains. This is vital, considering that over 70% of the fashion industry's carbon emissions come from upstream activities like fabric production, printing, and dyeing. By managing these processes locally, companies can actively improve environmental practices. For example, David Nieper, a UK-based manufacturer, has cut the energy required to produce each garment by 37.5% - from 8.03 kWh to 5.16 kWh - through renewable energy and more efficient machinery. Local production doesn't just reduce emissions; it also creates opportunities for ethical and innovative practices.

Skills Development and New Production Methods

Local manufacturing provides fertile ground for developing new skills and techniques. Activist apparel businesses in the UK are leading the way in fostering a local craft culture, where makers, clients, and communities work together. This collaborative approach encourages knowledge sharing and helps build economic resilience within local communities.

Moreover, producing locally ensures ethical labour practices. Workers benefit from fair wages, safe working conditions, and essential rights like maternity leave and secure contracts - protections that are often absent in overseas factories. By prioritising ethical standards, local production not only safeguards workers but also nurtures a skilled workforce capable of sustaining the UK's fashion industry for the long haul.

sbb-itb-24fa5d9

Challenges and Policy Support for Local Activist Apparel

Challenges Facing Local Apparel Producers

Local activist apparel makers in the UK are up against tough competition from global manufacturers. High production costs at home, the limited capacity of small mills, and restricted access to funding make it difficult for these producers to compete on price or scale with international companies. These hurdles highlight the urgent need for effective policy support to help sustain local activist apparel, building on the economic benefits previously mentioned.

Policy Measures to Support Local Production

Addressing these challenges calls for well-designed policy interventions. For instance, a textile-specific Extended Producer Responsibility (EPR) scheme - estimated to generate £150 million annually - could provide critical support for sustainable practices among local businesses. Additional measures, such as tax breaks, grants, subsidised access to modern equipment, and specialised training for garment workers, pattern cutters, and textile technicians, could help level the playing field. These steps would enable local producers, including brands like Rebelwear UK, to succeed not just by meeting ethical standards but also by achieving economic sustainability.

Conclusion: The Economic Case for Local Activist Apparel

Key Takeaways

Local production of activist apparel brings undeniable economic, social, and environmental benefits, as demonstrated by data and real-world examples.

From an economic perspective, producing locally generates meaningful jobs and ensures that money stays within the community, rather than being redirected to far-off corporations. Each pound spent locally supports a network of businesses, creating a ripple effect that strengthens the regional economy. On a social level, this model nurtures a network of skilled craftspeople who collaborate, share resources, and reduce waste - fostering a sense of community and cost efficiency. Environmentally, local production naturally limits manufacturing capacity, avoiding the overproduction issues that plague global fashion industries.

This approach challenges the outdated concept of trickle-down economics by focusing on direct local investment. Brands like Rebelwear UK exemplify this shift by embracing local production and adopting a degrowth strategy. This not only fights the harmful culture of overconsumption but also aligns with climate-conscious goals, offering sustainable livelihoods. Small-scale makers, by their very nature, avoid the wasteful practices of overproduction, such as destroying unsold stock, which are common in large-scale operations.

Reimagining clothing production in this way ties back to broader goals of environmental preservation and community well-being. It promotes thoughtful purchasing habits and bridges the gap between the clothes we wear and their impact on natural resources, labour conditions, and public health.

The conclusion is straightforward: producing activist apparel locally enriches communities, creates jobs, and supports a fashion economy that prioritises sustainability over excess.

Community Clothing: The Radical Act of Community

FAQs

How does producing activist apparel locally help reduce carbon emissions?

Producing activist apparel locally helps slash carbon emissions by minimising the need for long-distance transportation. With shorter supply chains, there’s a significant reduction in emissions from shipping and logistics - often some of the biggest culprits in a product’s overall carbon footprint.

On top of that, local production makes it easier to oversee sustainable practices. It ensures eco-friendly materials and methods take centre stage, benefiting the planet while also promoting ethical manufacturing standards within the community.

How do independent fashion brands help revitalise UK high streets?

Independent fashion brands are giving UK high streets a much-needed revival. By focusing on local production, these businesses help generate jobs, strengthen community connections, and provide opportunities for nearby suppliers and artisans. This creates a ripple effect that not only supports the local economy but also builds a sense of identity and pride within the community.

What sets these smaller brands apart is their ability to respond quickly to changing trends and customer preferences. Their distinctive products and fresh ideas draw people in, turning high streets into lively centres of activity, culture, and trade.

What policies can help support local activist apparel producers in the UK?

Supporting local activist apparel producers in the UK starts with introducing financial incentives, like grants or tax relief, to help small-scale businesses thrive while prioritising sustainable practices. Beyond financial support, investing in eco-friendly manufacturing infrastructure and offering skills training programmes can empower these producers to grow and innovate.

Establishing ethical standards and certifications is another key step. This would not only ensure transparency but also build trust among consumers who value responsible production. On top of that, promoting reshoring efforts - bringing production back to the UK - and implementing systems for recycling and circular production could strengthen the local industry. These actions would also align with broader sustainability goals, creating a more resilient and responsible apparel sector.